HSC Hydraulic Swing Clamp

Hydraulic Swing Clamps

Compact. Powerful. Reliable.

- Space-saving, compact design — ideal for high-volume series production in machining centers

- Rugged, reliable, and built for long-lasting performance

- Specially treated sliding surfaces ensure exceptionally smooth operation, outstanding performance, and extended service life

- Two series to fit your needs:

- HSC series — standard height

- HSX series — ultra-compact design with reduced height

- Material: High-strength carbon steel — extremely wear-resistant, durable, and robust

- Wide selection of piston sizes, mounting options, and connection types

- Optional stroke extensions available (see specifications)

- Clamping forces ranging from 1.66 kN to 26.39 kN

- Supplied fully assembled with clamping arm

- Operating pressure: 15 to 70 bar

- Double-acting hydraulic cylinder for efficient performance

- Operating temperature range: -10°C to +70°C

Important:

To maintain optimal performance, avoid excessive clamping speeds.

We recommend using a flow control valve for precise speed regulation.

Compatibility:

- The HSC series replaces the CHS series

- The HSX series replaces the Cl-HSC series

Customization:

Tailored modifications to meet specific customer requirements are available upon request.

➝ CAD data and pricing: available on request

Ordering Indication : HSC - MF-25-S-Rx90-E

| SERIES | HSC | |

| Mounting and piping types | Blank : Standard Line type M : Manifold type MF : Manifold type with Flow Control FA : Top Flange type TB : Threaded body FAM : Top Flange type with manifold FAMT : Top Flange type with flow control |

|

| Body size/ Hydraulic cylinder inside diameter [mm] |

ø25, ø32, ø40, ø50, ø63 | |

| Clamping arm type | S : Single side arm D : Double side arm |

|

| Rotating direction | R : Turn right (clockwise direction) L : Turn left (anti-clockwise direction) N : 0° (No swing) |

|

| Rotating angle | Standard angle : 90° (±2°) optional : 0°, 45° ±(2°), 60° (±2°) |

|

| Stroke Extention | optional stroke extention |

| Model No | Clamping force at 70bar [kN] | Swing stroke [mm] | Standard clamping stroke [mm] | Extended clamping stroke [mm] | Standard total stroke [mm] | Extended total stroke [mm] | Standard Oil capacity Clamp [cm3] | Extended Oil capacity Clamp [cm3] | Standard Oil capacity Unclamp [cm3] | Extended Oil capacity Unclamp [cm3] | eff. piston area Clamp [cm2] | eff. piston area Unclamp [cm2] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-25 | 1,66 | 11.5 | 13 | - | 24.5 | - | 12,03 | - | 5,81 | - | 4,91 | 2,37 |

| HSC-32 | 3,43 | 14.5 | 15 | 30 | 29.5 | 44.5 | 23,72 | 37,38 | 14,45 | 21,81 | 8,04 | 4,9 |

| HSC-40 | 6,03 | 14.5 | 15 | 30 | 29.5 | 44.5 | 37,05 | 55,89 | 25,43 | 38,36 | 12,56 | 8,92 |

| HSC-50 | 9,43 | 16 | 17 | 34 | 33 | 50 | 64,78 | 98,15 | 44,45 | 67,35 | 19,63 | 13,47 |

| HSC-63 | 14,88 | 16 | 17 | 34 | 33 | 50 | 106,3 | 155,8 | 70,16 | 106,3 | 31,16 | 21,26 |

| HSC-80 | 26,39 | 15 | 15 | - | 30 | - | 113.1 | - | 150.72 | - | 50.27 | 37.7 |

| ⬇︎ ⬇︎ HSX-Series Compact type with lower height ⬇︎ ⬇︎ | ||||||||||||

| HSX-25 | 1,66 | 9 | 13 | - | 22 | - | 10,80 | - | 5,21 | - | 4,91 | 2,37 |

| HSX-32 | 3,43 | 11 | 15 | 30 | 26 | 41 | 20,90 | 32,96 | 12,74 | 20,09 | 8,04 | 4,9 |

| HSX-40 | 6,03 | 11 | 15 | 30 | 26 | 41 | 32,66 | 51,50 | 22,41 | 35,34 | 12,56 | 8,62 |

| HSX-50 | 9,43 | 13 | 17 | 34 | 30 | 47 | 58,89 | 92,26 | 40,41 | 63,31 | 19,63 | 13,47 |

| HSX-63 | 14,88 | 13 | 17 | 34 | 30 | 47 | 99,92 | 146,45 | 63,78 | 99,92 | 31,16 | 21,26 |

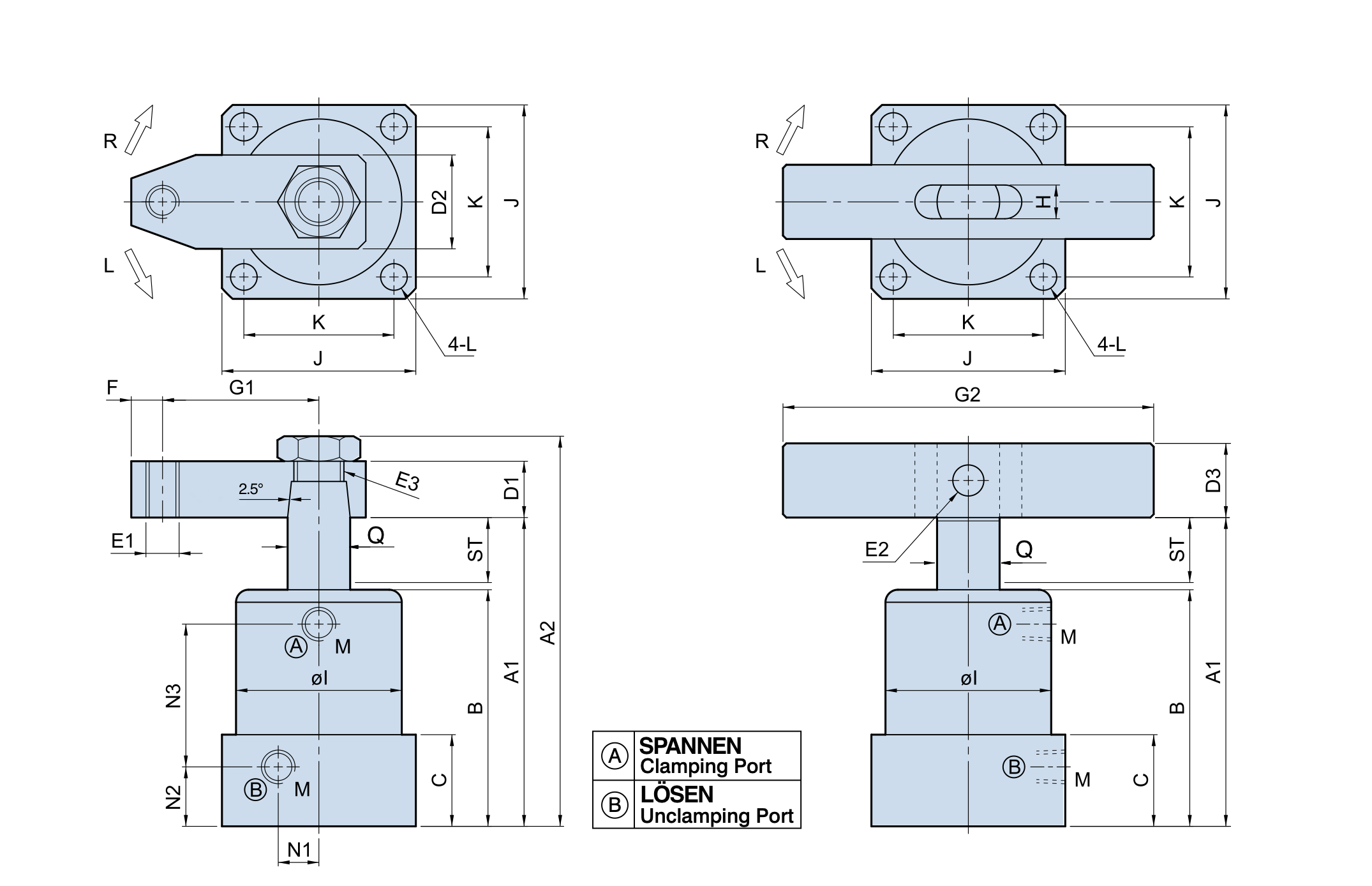

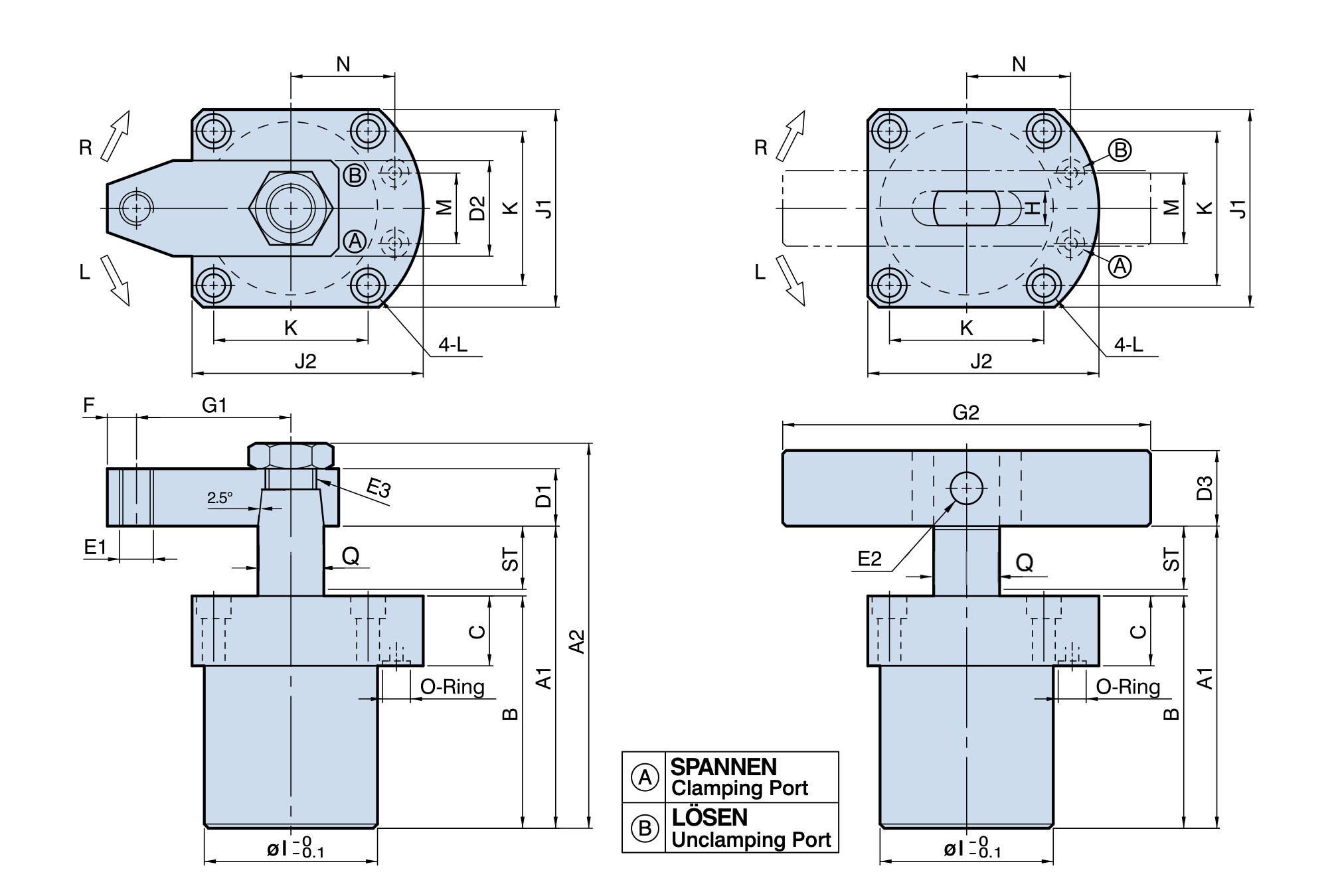

| MODEL | A1* | A2* | B | C | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | ΦI | J | K | L | M | N1 | N2 | N3 | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-25 | 104 | 127 | 76 | 27 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | ø46 | 52 | 40 | ø6.8 | PT1/8 | 8 | 17 | 46 | ø18 |

| HSC-32 | 118 | 144 | 85 | 30 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 56 | 44 | ø6.8 | PT1/8 | 10 | 19 | 52 | ø20 |

| HSC-40 | 123 | 150 | 90 | 30 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | PT1/8 | 12 | 19 | 57 | ø22.4 |

| HSC-50 | 137 | 167 | 100 | 34 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | PT1/4 | 15 | 21.5 | 63.5 | ø28 |

| HSC-63 | 142 | 177 | 105 | 34 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | PT1/4 | 17 | 22 | 68 | ø35.5 |

| HSC-80 | 142 | 187 | 105 | 34 | 28 | 52 | 34 | M16 | ø16 | M30×2 | 20 | 85 | 220 | 16 | ø100 | 110 | 87 | ø13 | PT1/4 | 17 | 25 | 65 | ø40 |

| HSC-32-E | 148 | 175 | 100 | 30 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 56 | 44 | ø6.8 | PT1/8 | 10 | 19 | 67 | ø20 |

| HSC-40-E | 153 | 180 | 105 | 30 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | PT1/8 | 12 | 19 | 72 | ø22.4 |

| HSC-50-E | 171 | 201 | 117 | 34 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | PT1/4 | 15 | 21.5 | 80.5 | ø28 |

| HSC-63-E | 176 | 211 | 122 | 34 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | PT1/4 | 17 | 22 | 85 | ø35.5 |

| ⬇︎ ⬇︎ HSX-Series compact type with lower height ⬇︎ ⬇︎ | |||||||||||||||||||||||

| HSX-25 | 101 | 124 | 76 | 27 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | ø46 | 52 | 40 | ø6.8 | PT1/8 | 8 | 17 | 46 | ø18 |

| HSX-32 | 115 | 140 | 85 | 30 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 56 | 44 | ø6.8 | PT1/8 | 10 | 19 | 52 | ø20 |

| HSX-40 | 120 | 148 | 90 | 30 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | PT1/8 | 12 | 19 | 57 | ø22.4 |

| HSX-50 | 134 | 166 | 100 | 34 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | PT1/4 | 15 | 21.5 | 63.5 | ø28 |

| HSX-63 | 139 | 175 | 105 | 34 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | PT1/4 | 17 | 22 | 68 | ø35.5 |

| HSX-32-E | 145 | 170 | 100 | 30 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 56 | 44 | ø6.8 | PT1/8 | 10 | 19 | 67 | ø20 |

| HSX-40-E | 150 | 178 | 105 | 30 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | PT1/8 | 12 | 19 | 72 | ø22.4 |

| HSX-50-E | 168 | 200 | 117 | 34 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | PT1/4 | 15 | 21.5 | 80.5 | ø28 |

| HSX-63-E | 173 | 209 | 122 | 34 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | PT1/4 | 17 | 22 | 85 | ø35.5 |

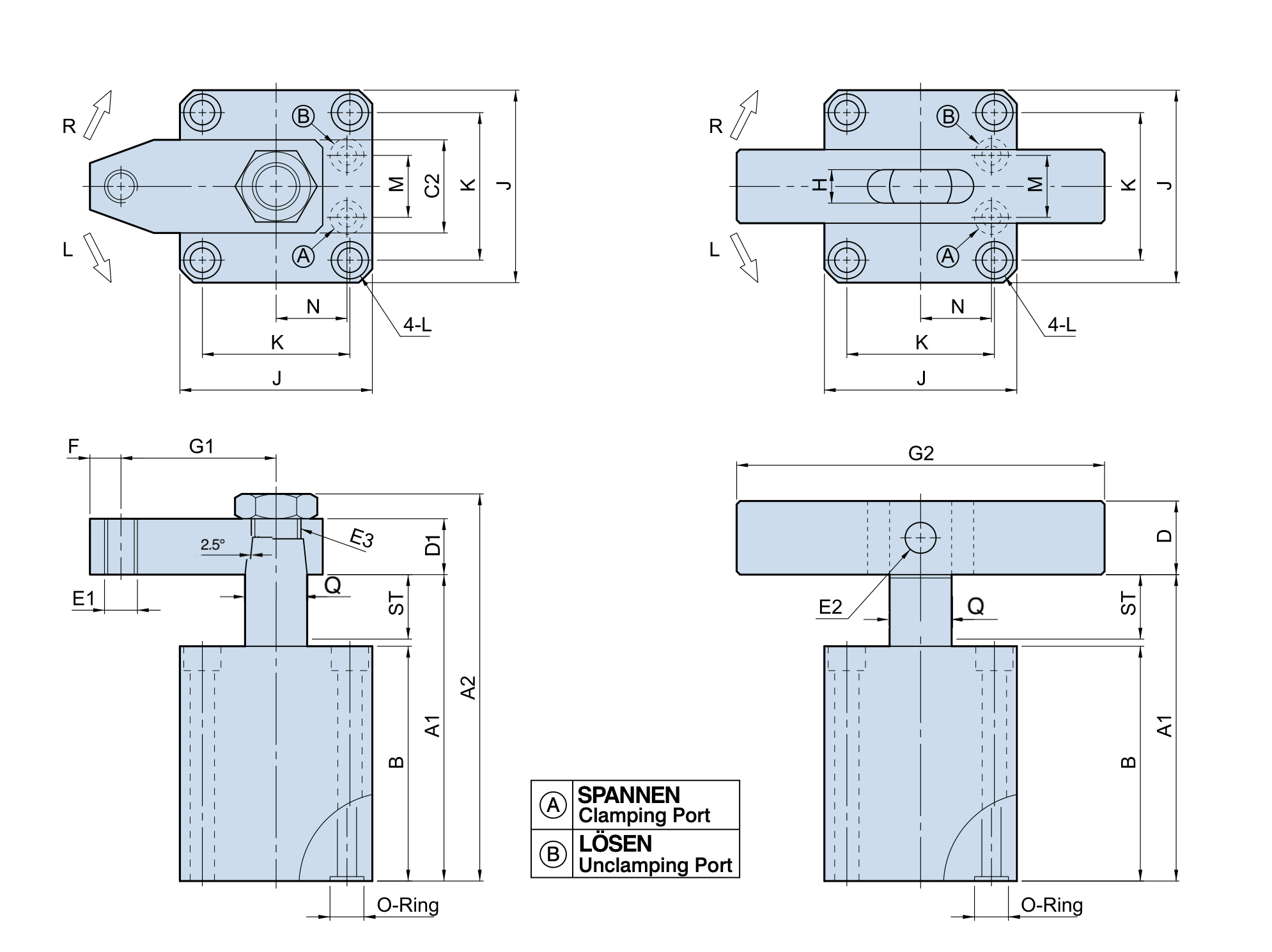

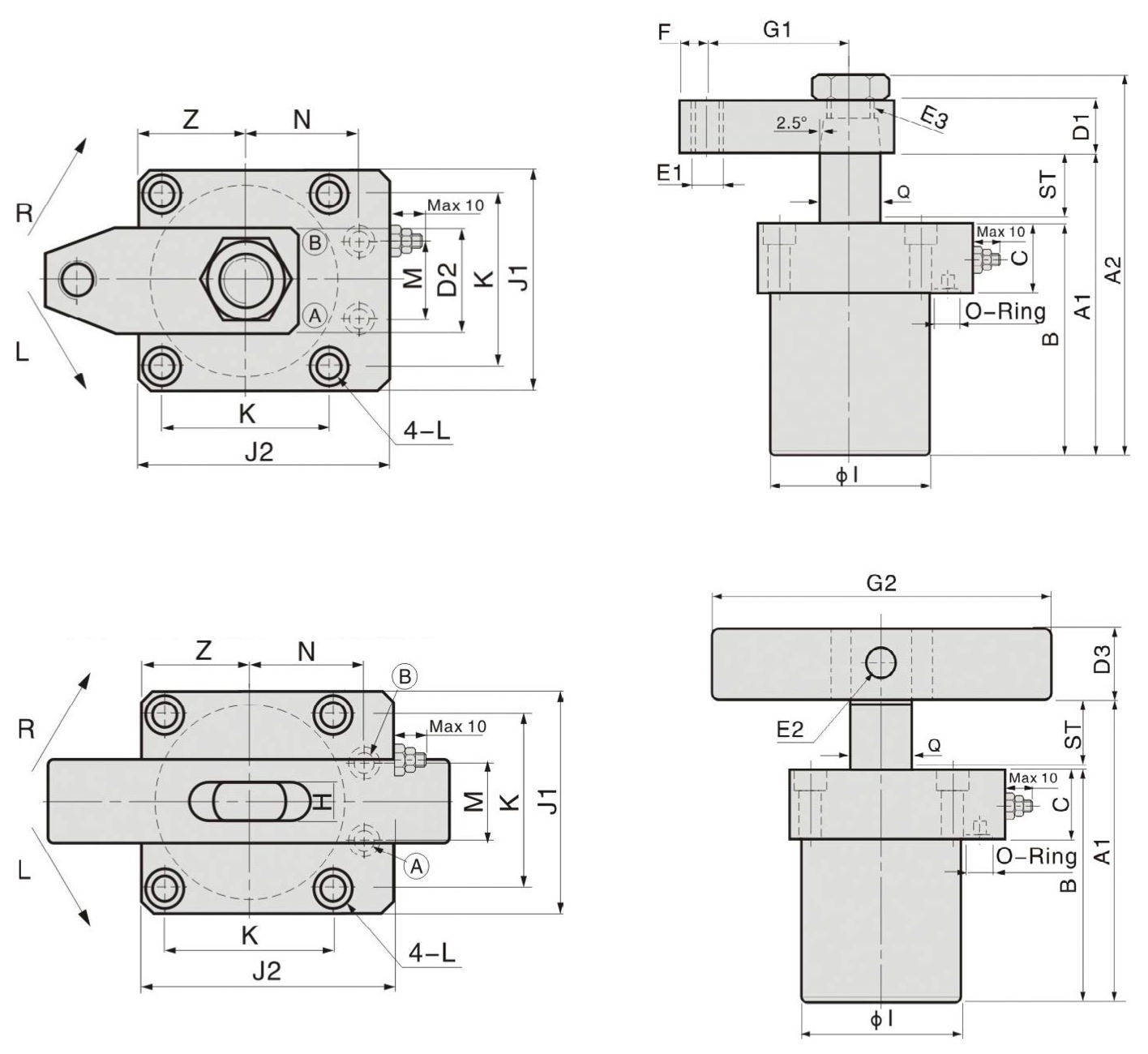

| MODEL | A1* | A2* | B | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | J | K | L | M | N | O-Ring | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-M25 | 104 | 127 | 76 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | 55 | 42 | ø6.8 | 18 | 20 | P7 | ø18 |

| HSC-M32 | 118 | 144 | 85 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | 57 | 44 | ø6.8 | 22 | 22 | P7 | ø20 |

| HSC-M40 | 123 | 150 | 90 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | 69 | 52 | ø9 | 26 | 26 | P8 | ø22.4 |

| HSC-M50 | 137 | 167 | 100 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | 75 | 58 | ø9 | 32 | 30 | P8 | ø28 |

| HSC-M63 | 142 | 177 | 105 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | 92 | 72 | ø11 | 40 | 37 | P9 | ø35.5 |

| ⬇︎ ⬇︎ HSX-Serie mit kompakterer Bauhöhe ⬇︎ ⬇︎ | ||||||||||||||||||||

| HSX-M25 | 101 | 124 | 76 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | 55 | 42 | ø6.8 | 18 | 20 | P7 | ø18 |

| HSX-M32 | 115 | 140 | 85 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | 57 | 44 | ø6.8 | 22 | 22 | P7 | ø20 |

| HSX-M40 | 120 | 148 | 90 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | 69 | 52 | ø9 | 26 | 26 | P8 | ø22.4 |

| HSX-M50 | 134 | 166 | 100 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | 75 | 58 | ø9 | 32 | 30 | P8 | ø28 |

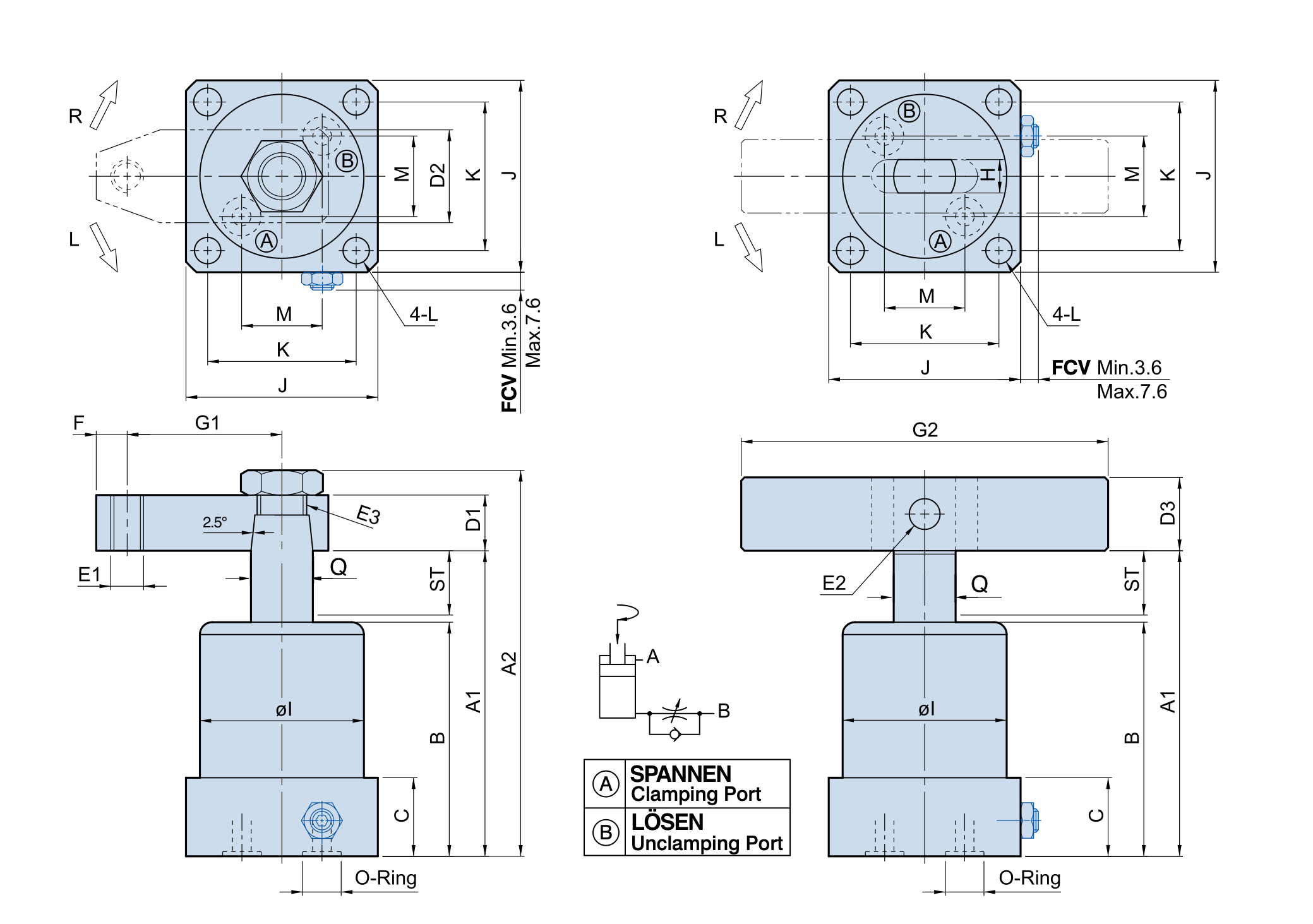

| MODEL | A1* | A2* | B | C | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | ΦI | J | K | L | M | O-Ring | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-MF25 | 104 | 127 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | ø46 | 55 | 42 | ø6.8 | 19 | P7 | ø18 |

| HSC-MF32 | 118 | 144 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 57 | 44 | ø6.8 | 21 | P7 | ø20 |

| HSC-MF40 | 123 | 150 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | 23 | P9 | ø22.4 |

| HSC-MF50 | 137 | 167 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | 28 | P9 | ø28 |

| HSC-MF63 | 142 | 177 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | 32 | P9 | ø35.5 |

| HSC-MF32-E | 148 | 175 | 100 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 57 | 44 | ø6.8 | 21 | P7 | ø20 |

| HSC-MF40-E | 153 | 180 | 105 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | 23 | P9 | ø22.4 |

| HSC-MF50-E | 171 | 201 | 117 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | 28 | P9 | ø28 |

| HSC-MF63-E | 176 | 211 | 122 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | 32 | P9 | ø35.5 |

| ⬇︎ ⬇︎ HSX-Serie mit kompakterer Bauhöhe ⬇︎ ⬇︎ | |||||||||||||||||||||

| HSX-MF25 | 101 | 124 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | ø46 | 55 | 42 | ø6.8 | 19 | P7 | ø18 |

| HSX-MF32 | 115 | 140 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 57 | 44 | ø6.8 | 21 | P7 | ø20 |

| HSX-MF40 | 120 | 148 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | 23 | P9 | ø22.4 |

| HSX-MF50 | 134 | 166 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | 28 | P9 | ø28 |

| HSX-MF63 | 139 | 175 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | 32 | P9 | ø35.5 |

| HSX-MF32-E | 145 | 170 | 100 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | ø50 | 57 | 44 | ø6.8 | 21 | P7 | ø20 |

| HSX-MF40-E | 150 | 178 | 105 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | ø54 | 63 | 48 | ø9 | 23 | P9 | ø22.4 |

| HSX-MF50-E | 168 | 200 | 117 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | ø66 | 72 | 57 | ø9 | 28 | P9 | ø28 |

| HSX-MF63-E | 173 | 209 | 122 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | ø80 | 88 | 70 | ø11 | 32 | P9 | ø35.5 |

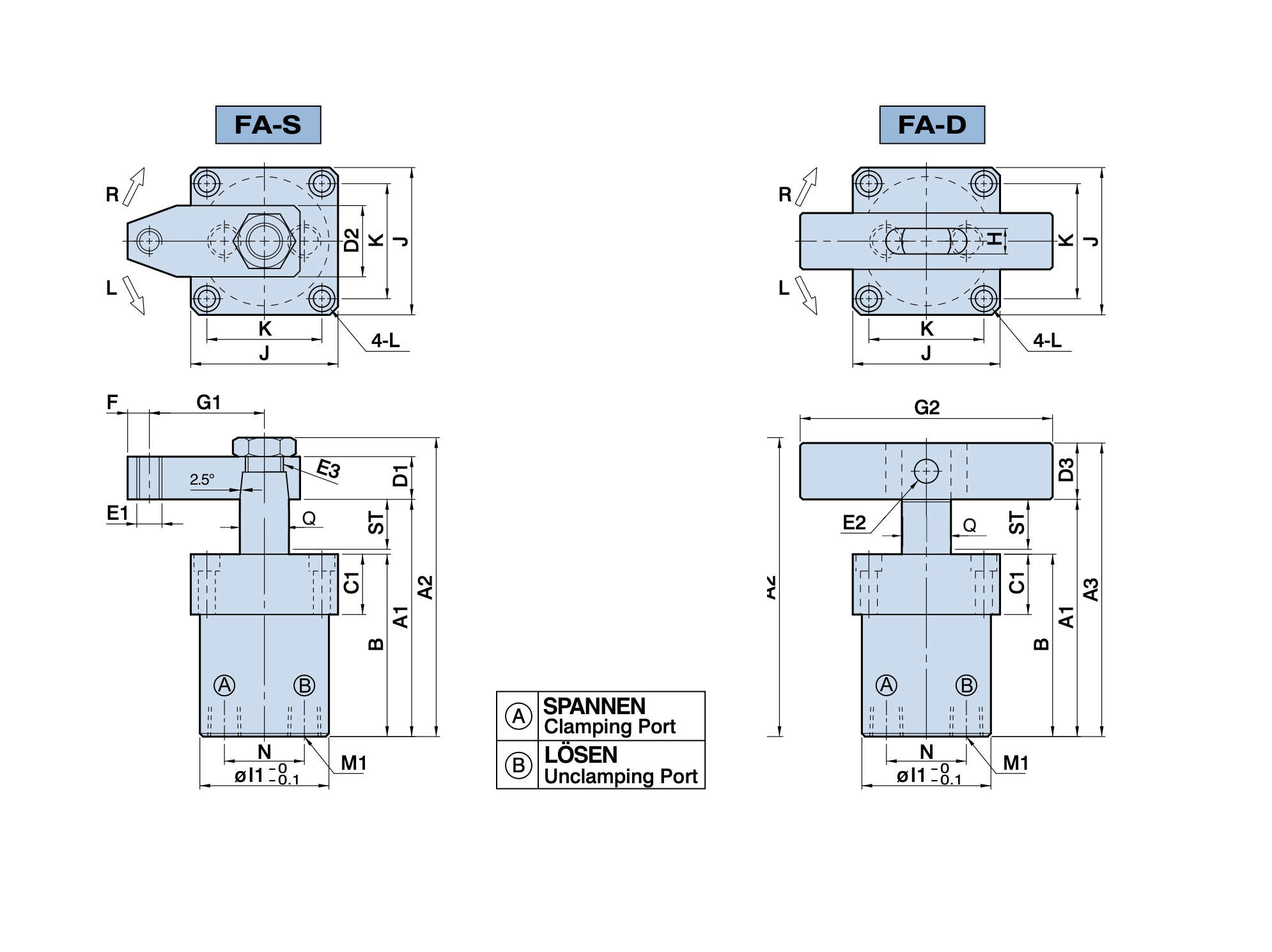

| MODEL | A1* | A2* | B | C1 | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | ØI1 | J | K | L | M1 | N | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-FA25 | 104 | 127 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | Ø45 | 53 | 40 | ø6.8 | PT1/4 | 28 | ø18 |

| HSC-FA32 | 118 | 144 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | Ø50 | 57 | 44 | ø6.8 | PT1/4 | 32 | ø20 |

| HSC-FA40 | 123 | 150 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | Ø58 | 69 | 52 | ø9 | PT1/4 | 40 | ø22.4 |

| HSC-FA50 | 137 | 167 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | Ø68 | 75 | 58 | ø9 | PT1/4 | 50 | ø28 |

| HSC-FA63 | 142 | 177 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | Ø81 | 90 | 70 | ø11 | PT1/4 | 63 | ø35.5 |

| ⬇︎ ⬇︎ HSX-Serie mit kompakterer Bauhöhe ⬇︎ ⬇︎ | |||||||||||||||||||||

| HSX-FA25 | 101 | 124 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | Ø45 | 53 | 40 | ø6.8 | PT1/4 | 28 | ø18 |

| HSX-FA32 | 115 | 140 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | Ø50 | 57 | 44 | ø6.8 | PT1/4 | 32 | ø20 |

| HSX-FA40 | 120 | 148 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | Ø58 | 69 | 52 | ø9 | PT1/4 | 40 | ø22.4 |

| HSX-FA50 | 134 | 166 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | Ø68 | 75 | 58 | ø9 | PT1/4 | 50 | ø28 |

| HSX-FA63 | 139 | 175 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | Ø81 | 90 | 70 | ø11 | PT1/4 | 63 | ø35.5 |

| MODEL | A1* | A2* | B | C2 | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | I2 | M2 | N | T1 2Stk | T2 | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-TB25 | 104 | 127 | 76 | 12 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | M45x1.5 | PT1/8 | 28 | 10 | ø65 | ø18 |

| HSC-TB32 | 118 | 144 | 85 | 12 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | M50x1.5 | PT1/8 | 32 | 11 | ø70 | ø20 |

| HSC-TB40 | 123 | 150 | 90 | 15 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | M55x1.5 | PT1/8 | 40 | 11 | ø70 | ø22.4 |

| HSC-TB50 | 137 | 167 | 100 | 15 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | M65x1.5 | PT1/8 | 50 | 12 | ø85 | ø28 |

| ⬇︎ ⬇︎ HSX-Serie mit kompakterer Bauhöhe ⬇︎ ⬇︎ | ||||||||||||||||||||

| HSX-TB25 | 101 | 124 | 76 | 12 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | M45x1.5 | PT1/8 | 28 | 10 | ø65 | ø18 |

| HSX-TB32 | 115 | 140 | 85 | 12 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | M50x1.5 | PT1/8 | 32 | 11 | ø70 | ø20 |

| HSX-TB40 | 120 | 148 | 90 | 15 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | M55x1.5 | PT1/8 | 40 | 11 | ø70 | ø22.4 |

| HSX-TB50 | 134 | 166 | 100 | 15 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | M65x1.5 | PT1/8 | 50 | 12 | ø85 | ø28 |

| MODEL | A1* | A2* | B | C | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | ØI | J1 | J2 | K | L | M | N | O-Ring | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-FAM25 | 104 | 127 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | Ø45 | 55 | 64 | 42 | ø6.8 | 20 | 28 | P6 | ø18 |

| HSC-FAM32 | 118 | 144 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | Ø50 | 57 | 65.5 | 44 | ø6.8 | 22 | 29 | P6 | ø20 |

| HSC-FAM40 | 123 | 150 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | Ø58 | 69 | 79 | 52 | ø9 | 26 | 34.5 | P9 | ø22.4 |

| HSC-FAM50 | 137 | 167 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | Ø68 | 75 | 87 | 58 | ø9 | 30 | 39 | P9 | ø28 |

| HSC-FAM63 | 142 | 177 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | Ø81 | 90 | 104.5 | 70 | ø11 | 32 | 46 | P9 | ø35.5 |

| ⬇︎ ⬇︎ HSX-Serie mit kompakterer Bauhöhe ⬇︎ ⬇︎ | |||||||||||||||||||||||

| HSX-FAM25 | 101 | 124 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | Ø45 | 55 | 64 | 42 | ø6.8 | 20 | 28 | P6 | ø18 |

| HSX-FAM32 | 115 | 140 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | Ø50 | 57 | 65.5 | 44 | ø6.8 | 22 | 29 | P6 | ø20 |

| HSX-FAM40 | 120 | 148 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | Ø58 | 69 | 79 | 52 | ø9 | 26 | 34.5 | P9 | ø22.4 |

| HSX-FAM50 | 134 | 165 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | Ø68 | 75 | 87 | 58 | ø9 | 30 | 39 | P9 | ø28 |

| HSC-FAM63 | 139 | 175 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | Ø81 | 90 | 104.5 | 70 | ø11 | 32 | 46 | P9 | ø35.5 |

| MODEL | A1* | A2* | B | C | D1 | D2 | D3 | E1 | E2 | E3 | F | G1 | G2 | H | ØI | J1 | J2 | K | L | M | N | O-Ring | Q | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSC-FAMT25 | 104 | 127 | 76 | 22 | 16 | 27 | 19 | M10 | ø8 | M14×1.5 | 10 | 50 | 140 | 9 | Ø45 | 55 | 64 | 42 | ø6.8 | 20 | 28 | P6 | ø18 | 27.5 |

| HSC-FAMT32 | 118 | 144 | 85 | 25 | 18 | 31 | 22 | M10 | ø8 | M16×1.5 | 10 | 55 | 160 | 10 | Ø50 | 57 | 65.5 | 44 | ø6.8 | 22 | 29 | P6 | ø20 | 28.5 |

| HSC-FAMT40 | 123 | 150 | 90 | 25 | 18 | 31 | 22 | M10 | ø10 | M18×1.5 | 10 | 60 | 160 | 10 | Ø58 | 69 | 77 | 52 | ø9 | 26 | 34.5 | P6 | ø22.4 | 34.5 |

| HSC-FAMT50 | 137 | 167 | 100 | 30 | 20 | 37 | 25 | M12 | ø12 | M20×1.5 | 12 | 65 | 180 | 12 | Ø68 | 75 | 87 | 58 | ø9 | 30 | 39 | P9 | ø28 | 37.5 |

| HSC-FAMT63 | 142 | 177 | 105 | 30 | 23 | 48 | 32 | M16 | ø15 | M24×2 | 15 | 75 | 200 | 15 | Ø81 | 90 | 104.5 | 70 | ø11 | 32 | 46 | P9 | ø35.5 | 45 |