HPS Hydraulic Swing Clamp

Hydraulic Swing clamping cylinder :

- This series is ideal for workpiece clamping which requires a sufficient space for convenient workpiece loading and unloading and high pressure clamping.

- It provides swing motion (do not clamp workpiece) and vertical holds down motion.

- The swing clamp cylinder employs Germany oil seal and European parts.

- Inside surface of cylinder barrel is specially treated,featuring maximum smoothness, high performance and long service life.

- For maximum oil feeding speed, refer to specifications.Do not exceed oil feeding speed to avoid too high swing speed.

- ln case improper swing speed occurs,it is suggested to equip with an additional oil flow control valve to reduce oil feeding speed.

- Max. operating pressure: 250 bar (kgf/cm2)

- Min. operating pressure: 70 bar (kgf/cm2)

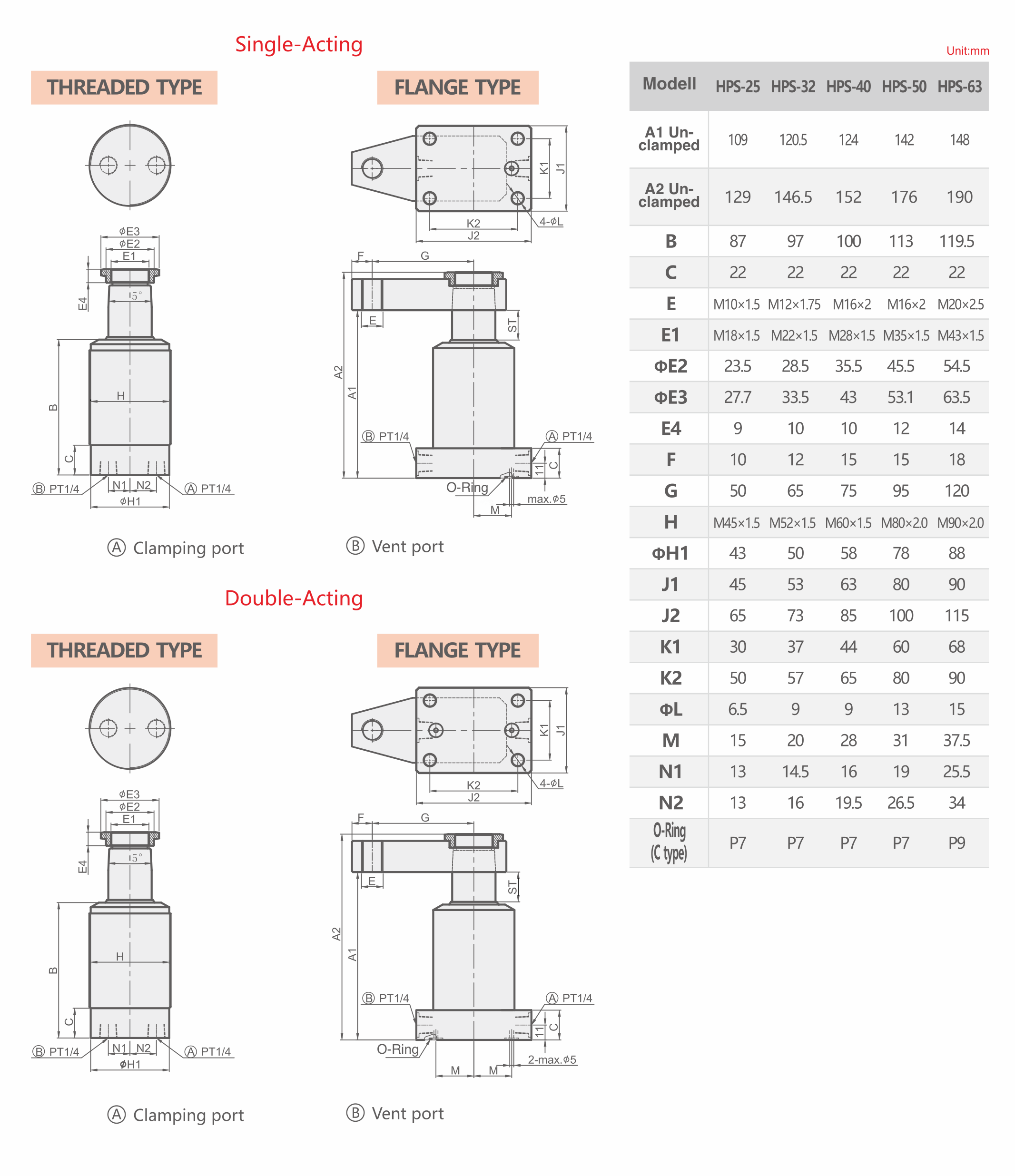

- optional Single acting and double acting

Note :

- The acting speed of clamping-unclamping should be slowed down.

- For customized clamp arm, please don't exceed 1.5 times of the original length and weight.

- We are able to realize customized modifications

- Only double acting type available in Europe !

- CAD-data and Prices: on Request

Ordering Indication : HPS- 25-S-A-RX90

| SERIES | HPF | |

| Hydraulic cylinder-Inside diameter | ø25, ø32, ø40, ø50, ø63 | |

| Acting type | S : single acting | |

| D : doouble acting | ||

| Mounting type | A :Threaded body B :Line type C :Manifold type |

|

| Rotating direction | R :Turn right (clockwise direction) L :Turn left (anti-clockwise direction) |

|

| Rotating angle | Standard angle :90° (±2°) optional :30° (±2°) , 45° (±2°), 60° (±2°) |

| Model | -Single acting- clamping force at 250 bar [kN] | -Double acting- clamping force at 250 bar [kN] | Swing stroke [mm] | Clamping stroke [mm] | Total stroke [mm] | Oil capacity Clamp [cm3] | Oil capacity Unclamp [cm3] | eff. piston area Clamp [cm2] | eff. piston area Unclamp [cm2] |

|---|---|---|---|---|---|---|---|---|---|

| HPS-25 | 3,8 | 4,4 | 8 | 11 | 19 | 3,18 | 8,83 | 1,77 | 4,9 |

| HPS-32 | 6,5 | 7,8 | 9 | 13 | 22 | 6,9 | 17,7 | 3,13 | 8,04 |

| HPS-40 | 9,4 | 11,0 | 9 | 13 | 22 | 9,95 | 27,65 | 4,52 | 12,56 |

| HPS-50 | 15,8 | 17,6 | 12 | 15 | 27 | 18,38 | 51,05 | 7,07 | 19,63 |

| HPS-63 | 25,6 | 28,8 | 12 | 15 | 27 | 27,69 | 74,81 | 11,54 | 31,16 |

| Model | Stroke | A1 Unclamped | A2 Unclamped | B | C | E | E1 | E2 | E3 | E4 | F | G | I | I1 | J1 | J2 | K1 | K2 | L | M | N1 | N2 | O-Ring |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HPS-25 | 19=8+11 | 107.5 | 129 | 87 | 22 | M10x1.5 | M18x1.5 | ø23.5 | 27.7 | 9 | 10 | 50 | M45x1.5 | ø43 | 45 | 65 | 30 | 50 | ø6.5 | 15 | 13 | 13 | P7 |

| HPS-32 | 22=9+13 | 120.5 | 146.5 | 97 | 22 | M12x1.75 | M22x1.5 | ø28.5 | 33.5 | 10 | 12 | 65 | M52x1.5 | ø50 | 53 | 73 | 37 | 57 | ø9 | 20 | 14.5 | 16 | P7 |

| HPS-40 | 22=9+13 | 123.5 | 152.5 | 100 | 22 | M16x2 | M28x1.5 | ø35.5 | 41.6 | 10 | 15 | 75 | M60x1.5 | ø58 | 63 | 85 | 44 | 65 | ø9 | 28 | 16 | 19.5 | P7 |

| HPS-50 | 27=12+15 | 142 | 177 | 113.5 | 22 | M16x2 | M35x1.5 | ø45.5 | 53.1 | 12 | 15 | 95 | M80x2.0 | ø78 | 80 | 100 | 60 | 80 | ø13 | 31 | 19 | 26.5 | P9 |

| HPS-63 | 27=12+15 | 148 | 190 | 119.5 | 22 | M20x2.5 | M43x1.5 | ø54.5 | 63.5 | 14 | 18 | 120 | M90x2.0 | ø88 | 90 | 115 | 68 | 90 | ø15 | 37.5 | 25.5 | 34 | P9 |