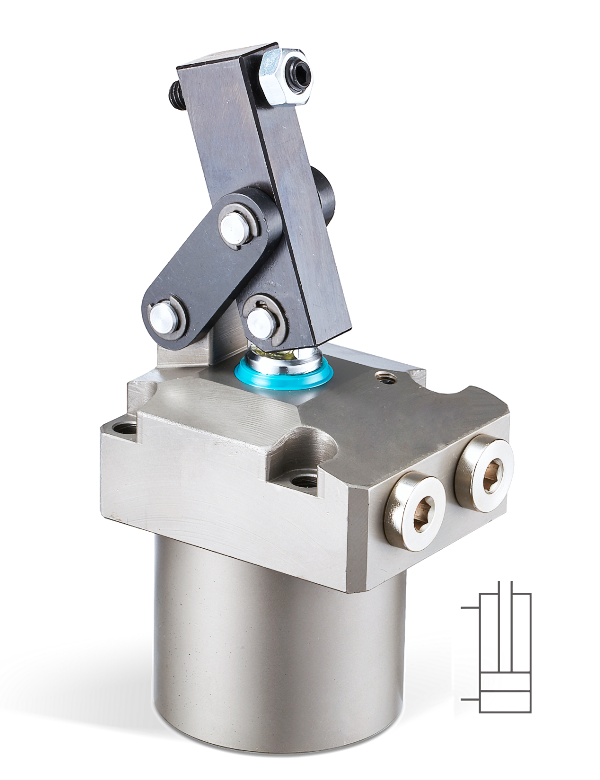

HLKP Hydraulic Link Clamp - double acting

Hdyraulic Link Clamp - Hydraulic Cylinder :

- very compact series with low flange design

- suitable especially for compact and light fixtures with high clamping forces.

- double acting type

- High clamping forces 2,7kN up to 31kN

- Clamping force depends on the clamp arm length and hydraulic pressure

- complete with clamping arm and screw

- Use flow control valve for meter-in control.

- Min. operating pressure : 10bar

- Max. operating pressure : 70bar

- Range of Temperature : -10 ~ +70°C

- various sizes and optional in manifold type with O-Ring (Y) or line type with G-port piping (G)

➝ CAD-files and prices on Request !

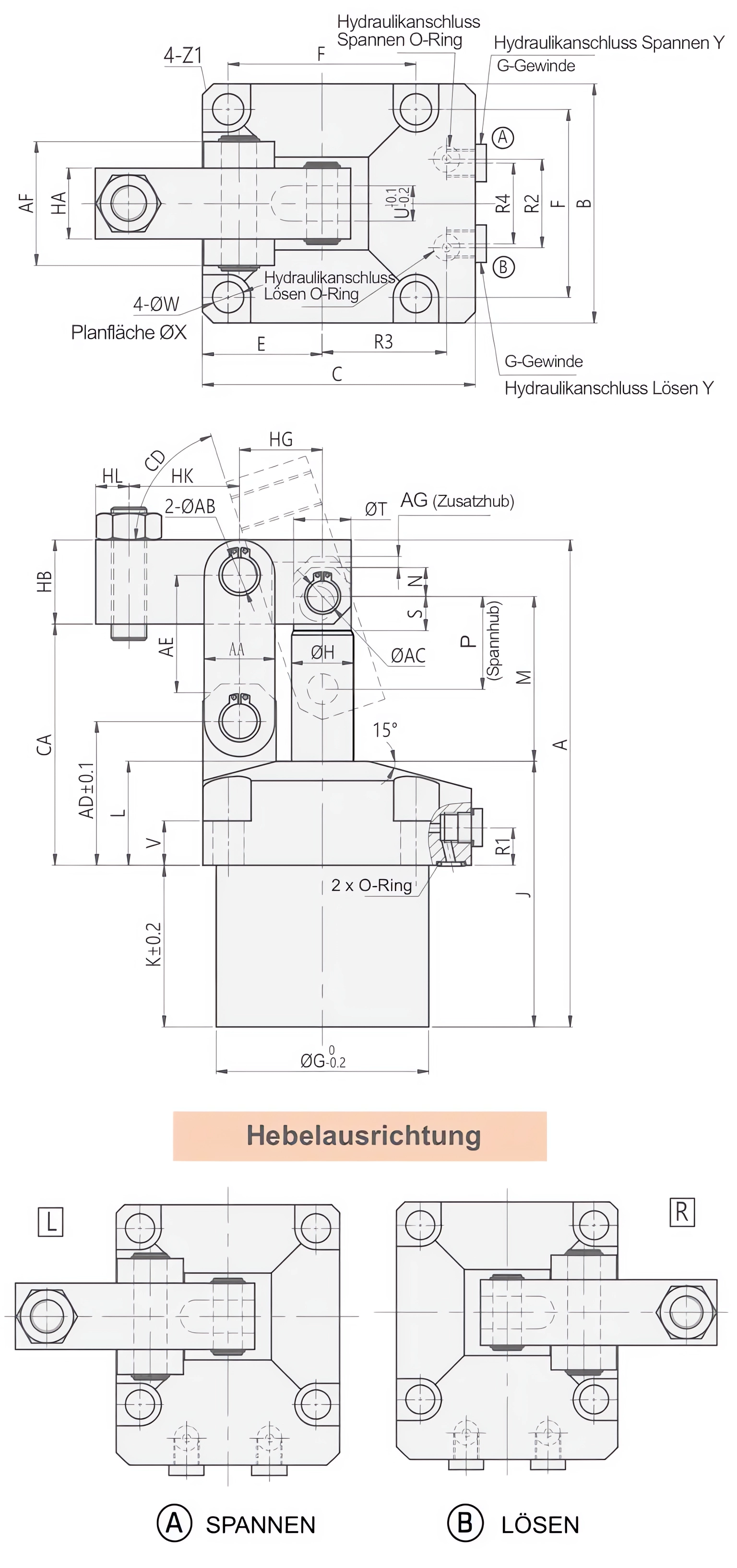

Ordering Indication : HLKP - 040 R

| ① | SERIES | HLKP | |

| ② | Body size | 040 / 048 / 055 / 065 / 075 / 105 | |

| ③ | Lever direction | Blank: Standard front side (with G Thread Port) R: Right side L: Left side |

| Model No. | Clamping force at 70 bar (kN) | Clamping stroke (mm) | Total stroke (mm) | Oil capacity Clamp [cm3] | Oil capacity Unclamp [cm3] | eff. piston area clamp [cm2] | eff. piston area unclamp [cm2] | CAD |

|---|---|---|---|---|---|---|---|---|

| HLKP-040 | 2,83 | 17,5 | 20,5 | 7,7 | 10 | 3,77 | 4,9 | |

| HLKP-048 | 3,91 | 20,5 | 23,5 | 13 | 16,7 | 5,56 | 7,1 | |

| HLKP-055 | 4,86 | 23 | 26 | 21 | 25 | 8,06 | 9,6 | |

| HLKP-065 | 8,14 | 26,5 | 29,5 | 38,9 | 44,8 | 13,2 | 15,2 | |

| HLKP-075 | 13,46 | 33 | 36 | 74,5 | 88,6 | 20,66 | 24,6 | |

| HLKP-105 | 20,20 | 42 | 45 | 145,5 | 173,3 | 32,35 | 38,5 |

| Model | HLKP-040 | HLKP-048 | HLKP-055 | HLKP-065 | HLKP-075 | HLKP-105 |

|---|---|---|---|---|---|---|

| A | 97 | 108 | 119,5 | 140 | 166 | 199 |

| B | 45 | 50 | 57 | 70 | 86 | 108 |

| C | 55 | 60 | 66 | 82 | 96 | 120 |

| E | 22.5 | 25 | 28.5 | 35 | 43 | 54 |

| F | 35 | 40 | 46 | 56 | 68 | 88 |

| G | 39 | 47 | 53 | 63 | 78 | 100 |

| H | 12 | 14 | 14 | 16 | 22.4 | 28 |

| J | 60 | 66 | 71 | 83 | 95 | 112 |

| K | 33.5 | 39.5 | 42.5 | 47 | 55 | 65 |

| L | 26.5 | 26.5 | 28.5 | 36 | 40 | 47 |

| M | 28.5 | 32 | 34.5 | 40 | 49 | 61.5 |

| N | 5 | 6 | 6 | 8 | 11 | 13 |

| P | 17.5 | 20.5 | 23 | 26.5 | 33 | 42 |

| Q | 2 | 2 | 2 | 2 | 2.5 | 2.5 |

| R1 | 12.5 | 12.5 | 12.5 | 14 | 14 | 21 |

| R2 | 22 | 24 | 28 | 36 | 45 | 50 |

| R3 | 25 | 28 | 30.5 | 36 | 42 | 57 |

| R4 | 20 | 22 | 26 | 30 | 38 | 50 |

| S | 6.5 | 7 | 7 | 9 | 10.8 | 14.5 |

| T | 10 | 12 | 12 | 14 | 20 | 26 |

| U | 6 | 6 | 8 | 10 | 11 | 16 |

| V | 18 | 17 | 17 | 20 | 20 | 20 |

| W | 5.5 | 5.5 | 6.8 | 9 | 11 | 14 |

| X | 10 | 10 | 12 | 15 | 18.5 | 20 |

| Y | G1/8 | G1/8 | G1/8 | G1/4 | G1/4 | G3/8 |

| Z1 | C1.5 | C2.5 | C2.5 | C3 | C3.5 | C5.5 |

| Q1 | Ø13.5 | Ø16 | Ø23 | Ø28 | Ø33.5 | Ø53 |

| O-Ring | P7 | P7 | P7 | P8 | P8 | P10 |

| AA | 11 | 13 | 15 | 19 | 25 | 32 |

| AB | 6 | 6 | 8 | 10 | 14 | 16 |

| AC | 6 | 6 | 6 | 8 | 12 | 14 |

| AD | 34 | 36 | 39 | 48 | 54.5 | 65 |

| AE | 24 | 26 | 30 | 35.5 | 44 | 53 |

| AF | 21 | 21 | 28 | 37 | 46 | 56 |

| AG | 3 | 3 | 3 | 3 | 3 | 3 |

| BC | 4 | 4 | 4 | 6 | 6 | 8 |

| CA | 49.5 | 52.5 | 57 | 68 | 80 | 96 |

| CB | 48 | 59.6 | 67.3 | 78.7 | 98.2 | 133.5 |

| CC | 80.2 | 92.5 | 101.3 | 120.4 | 144.7 | 189.2 |

| CD | 69° | 71° | 70° | 70° | 69° | 72° |

| HA | 12 | 12 | 16 | 19 | 22 | 32 |

| HB | 14 | 16 | 20 | 25 | 31 | 38 |

| HG | 16.5 | 18.5 | 21 | 24.5 | 30.5 | 37.5 |

| HK | 120 | 23.5 | 29 | 32 | 39 | 50 |

| HL | 6 | 6 | 8 | 10 | 11 | 15 |